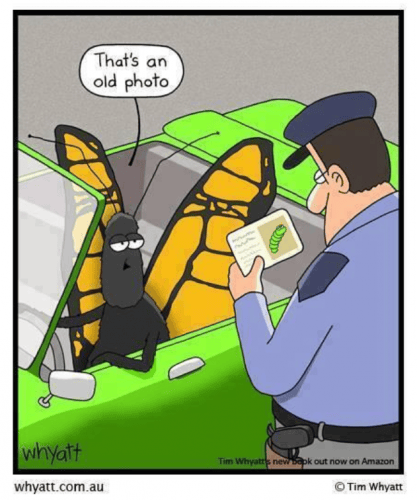

At Shapeways, we have a tradition of giving internal projects an animal name that captures its essence. In this case, the problem we wanted to tackle is a big hairy one with lots of sections and legs, across all our teams — like a caterpillar. The problem is: rejections. Our goal is to dramatically improve how we give you feedback when a product you have ordered cannot be manufactured using 3D printing. Historically, you might have received our standard rejection email that said, “After taking a closer look, we cannot print one of the models in order # …” You probably spent hours designing, or searching for, that one unique product that is not for sale anywhere else and then we had to tell you to start over! We understand that this could be a very disappointing message. With Project Caterpillar, our aim is to turn design feedback and iteration into a positive experience, and watch our caterpillar eventually go into its chrysalis and emerge as a beautiful butterfly.

It has been half a year since we formed a team to tackle this issue head on. The team consists of community managers, operational directors, software developers, customer service representatives, product managers, and supply chain coordinators. It has been all hands on deck to fight what many of you felt is the worst experience when shopping, selling or making products at Shapeways: getting a rejection.

Why is this such a hairy problem?

At Shapeways we always aim to quickly and affordably turn your ideas from digital designs into real products, but due to the limitations in 3D printing, some designs just can’t be brought to life in their current form. To help clarify how to best design for 3D printing, we provide tools on our website that give you the information you need to make the best possible decisions while designing a product, but it’s not always that simple. Usually we know what will print, but we are also learning with our customers every day — you are pushing the limits of the technology, and we’re right along with you, even if sometimes we have to give you bad news that we can’t produce your product as you’ve built it.

But really, why is this so hard? Here are some of the biggest issues:

- Well, the first thing was to accept that it is OK to fail. We should take chances, and if that means we try it a few times and we still can’t print your product, that’s OK so long as we give you actionable feedback once we figure it out–and then we can keep learning about what works and what doesn’t.

- For makers in particular, most of the time we have never seen these products before, and we are not sure what you want! Should that really small propeller actually be attached to the plane? Is it OK if you have a ton of powder stuck inside? We are guessing, and need better ways to understand your intentions and communicate.

- One of the biggest challenges has been consistency: every model gets checked by hand, and we have dozens of production partners who are looking at thousands of models that have been made 5 minutes or 5 years ago in 40+ materials. This is a lot of people and data to coordinate. So a huge part of our focus was around training our 3D print engineers, and on giving you useful, timely feedback.

- You might have noticed that we publish guidelines and not rules. That’s partially because we want to continue to allow you to push creative boundaries, and also because creating designs with 3D software that also observe rules of physics can be subjective. For instance, a thin wire will work if the rest of the geometry is structurally sound, but a hard “no thin wire” rule would have eliminated this option. So it’s a lot of art, and less science than we would prefer, especially when the technology improves every day.

With this in mind and the goal of turning rejections into resolutions, our teams have been working around the clock to surface potential issues with your models as soon as possible, to provide actionable, consistent feedback when there is an issue, and to make the rejection experience less frustrating for anyone that still receives that disappointing message.

Trust us, we know we’re not quite there yet and we will continue to do everything in our power to accommodate your needs. Still, we wanted to take this opportunity, half a year down the line to reflect on where we came from and where we are now.

Some of the steps we took to reduce rejections

#1 Thin Wall Checking and Fixing.

When we looked into the data for why we had to reject certain designs, it became clear that the biggest issue preventing them from passing our manual checks was in their structural integrity: they had “thin walls” and weren’t strong enough to withstand the whole production process. While a large part of the process your product goes through is just bits and bytes, after a product is taken out of the 3D printer, it is physically touched at least 5 times in cleaning, quality checks, packing, and more. While our printers can produce nearly anything, you can imagine when blasting excess material off your model with high pressured air, your model will need some strength to survive. Soon enough our team decided to surface critical checks of your models on upload; the thin wall checker was one of the first of these tools released on our website. Shortly followed by the thin wall fixer, which in many cases can help solve issues with your models that would have otherwise caused the models to be rejected. We have lots of huge plans for this area, so we can show you the path, right at upload, to producing your model successfully.

See how some of our materials are processed from start to finish in this video playlist:

#2 Print It Anyway.

Another feature many of our most loyal and seasoned community members have been requesting for a long time is the option to go ahead with manufacturing, even if the model doesn’t pass manual checks. Print It Anyway is an option at checkout, that enables you to test your most complicated designs and learn from the actual, physical outcome. Our production crew will always do their very best to ship models in the desired level of quality, and this is no different when selecting Print It Anyway. If a feature on your model cannot make it through the whole production process without slight issues, we would still ship the model to you, so you can hold your model in your own hands, learn from it, and iterate. We learn from your PIAs too!

#3 Detailed Manual Checks.

While all of this work was in progress, our 3D printing engineers have been aiming to provide the complete feedback to slightly adjust your design if it failed thorough manual checks. Instead of surfacing just one issue, they now describe all the issues at once. In practice, this means you would not end up in an endless circle of rejection and updating your model. If you do experience a rejection, the reasons are also now available on your model edit page as well as in your original email.

#4 Checking Consistency & #5 Print Success Rates.

We know that the most infuriating thing is to get a rejection of a model that you printed before, and we have paid special attention to fixing that. Indeed we have had a few big hiccups managing these models along the way, but we have improved dramatically, down to < 0.3% of models, and we are still trying to make it better. The consistency of manual checks is continuously monitored and the print success rate of your model is now shown on your model edit page. This way you see the same metrics we look at to judge success through the process.

What’s next?

We’re happy to report that we’ve made some significant progress, reducing by half the number of times we have to tell you that we can’t print your model. When we do have to give you the bad news, most of the time it’s within 24 hours, and it’s always accompanied by a detailed explanation from a trained 3DP engineer. While we think this improves your experience, we know this is just the tip of the iceberg, especially if you’re someone who still can’t get your product made. We promise that we’re committed to helping you bring amazing products to life, and there are still lots of features and improvements lined up.

This caterpillar is not quite ready to come out of its chrysalis, at least not until we have found a solution that eradicates your frustration and disappointment, but we will continue to listen to your feedback and we will learn from you every day.

Thank you,

Team Caterpillar

One thing that would help with consistency across prints would be an option to set the print orientation. For example with FUD, I can often tell which way the model was orientated during printing due to marks left from the support material. In some print orientations this marks are not an issue (sometimes they even add to the model), but in others they will appear on a surface which ruins the model. Given that I know which surfaces it is important to try and keep clear of support material allowing me to set the print orientation would really help and would ensure multiple prints were consistent.

Thanks for the feedback, Mark! Definitely hear you on the consistency and impact on your design. Print orientation is definitely something we’re gearing up for…hang tight!

I strongly support the request for setting the print orientation. It would be a great feature, and I would pay extra for it – after all, it adds an additional constraint to the Shapeway team to pack the models for printing.

One of the plastic dimensions is often a tad short, I could place that in the most uncritical dimension. Also printing direction affects mechanical properties of the printed part. Controlling print direction increases consistency, and overall produces better models.

Thanks Klaus! I’ll make sure the team gets your feedback.